For the successful realisation of your project, theoretical calculations are often not sufficient. To carry out feasibility studies and pilot tests using Thin Film, Wiped Film and Short Path distillation, a well-equipped pilot plant is available to you at our UIC headquarter in Alzenau. Here, our experts individually configure suitable laboratory and pilot plants for your distillation applications in order to develop the ideal separation process.

Decades of experience, matched with accumulated knowledge, enable us to carefully plan these tests in partnership with our customers.

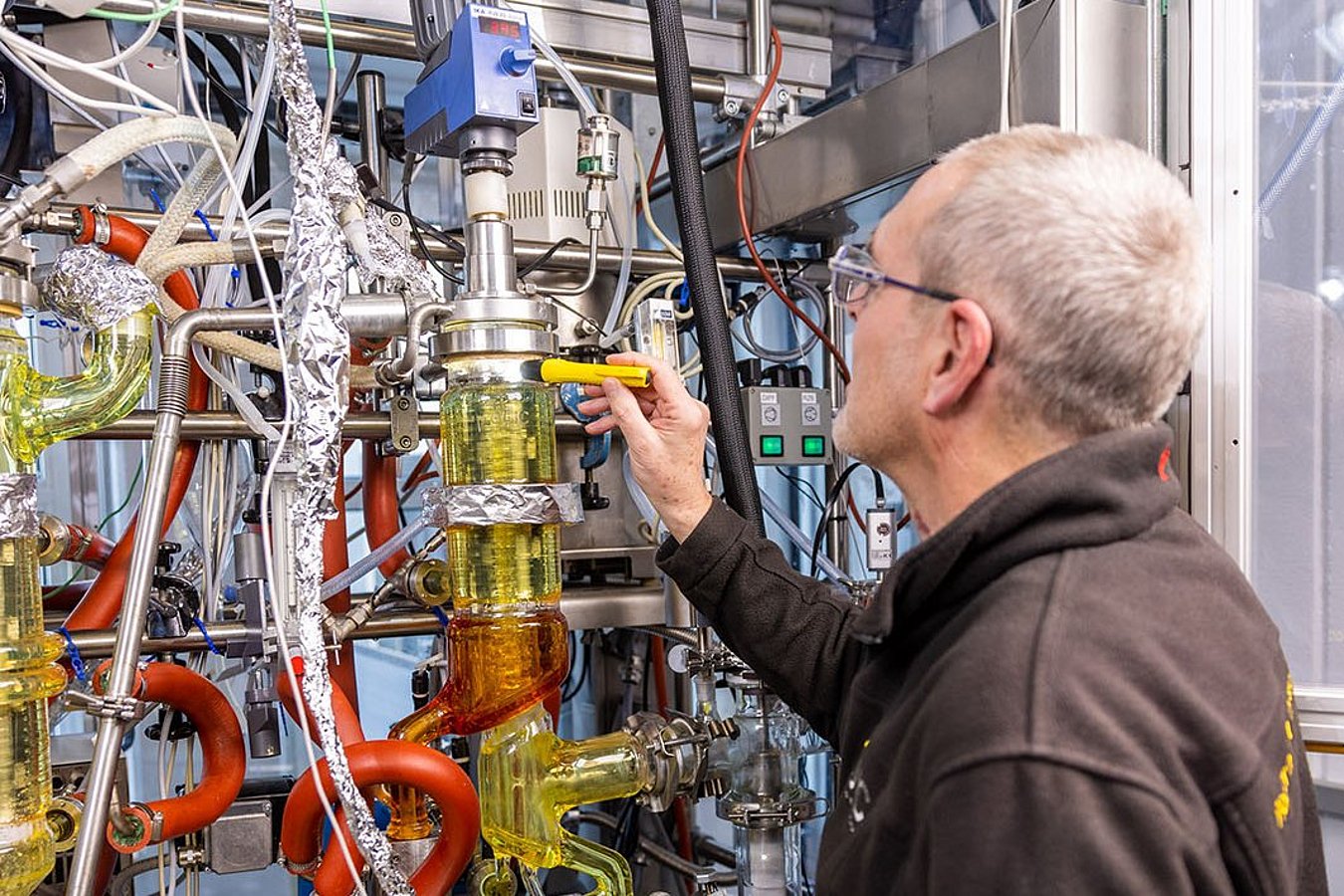

The maximum flexibility of our pilot plants allows us to use numerous combinations of different components (Thin Film evaporator, Short Path evaporator, rectification column, and many more) to perform your separation task at its best.

The basis for a successful process solution is created in our laboratory facilities. Our units, made of glass, allow us to observe product behavior (foaming, splashing, deposits, etc.) during distillation. These observations, together with initial analytical measurements, are essential to subsequent pilot testing and the resulting plant design. Small quantities of product (0,1 - 20 kg) are sufficient for these preliminary laboratory scale tests.

For feasibility studies, both short path and thin film evaporators are available, which can be operated in different combinations.

Depending on the product properties, we can equip our evaporators with different wiping systems.

Our range of services, also includes sample distillations, of course.

Further process development and process optimization take place with the help of our pilot plants. Under real production conditions, the optimal throughput as well as the achievable quality and yield of a later large-scale industrial plant are determined here. Based on our scale-up trials, we provide you with a process guarantee for your customised plant.

A central analytical department is available. Qualified and experienced professionals are able to monitor the trials as well as the toll distillation campaigns with suitable analytical methods.

Entrust us with your projects and benefit from our experience and expertise

As your reliable partner, the strictest confidentiality of your sensitive product information is of particular importance to us. As a service provider in plant engineering, we have no production or marketing interest in your products.